Our proprietary membrane is based on Silicon Carbide (SiC) and can be used to filter various sources of contaminated water to the highest reuse-, portable- or discharge standards.

How does it work

A slight vacuum is applied to the membrane to pull water through the membrane pores. SiC is one of the few membrane materials that is naturally and permanently hydrophilic, meaning organic foulants, including oil, are repelled by the membrane while water is naturally drawn in.

Solids, pathogens, and other contaminants are blocked by the membrane pores and are retained on the surface.

Operation

A slight vacuum, typically around 0,1 - 0,2 bar is applied to the membrane to pull water through. Solids and other contaminants are blocked by the membrane pores and are retained on the surface. Periodically, water is reversed back through the membranes to dislodge and remove solids that have accumulated on the surface.

In some applications, air is bubbled up in between plates to provide a scouring action which further helps keep the membrane clean. Various types of spray washes can be employed to quickly and effectively remove solids from the membrane surface.

The SiC membranes are configured into a module that can be configured to meet the needs of any project. SiC modules can be easily stacked to fit any basin size, creating unprecedented flexibility within the industry.

The module consists of three basic elements:

Membrane module

Top permeate module

Bottom diffusor case module

Where is siC used?

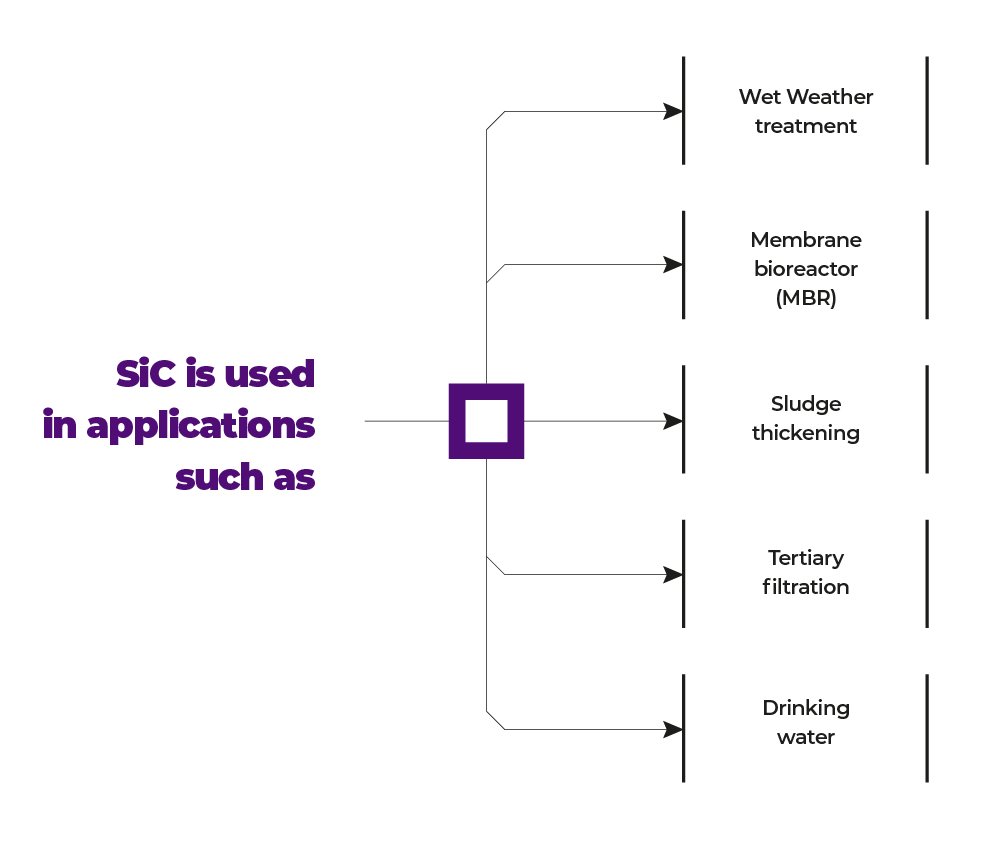

Our SiC membranes are used in a wide variety of water and wastewater applications in both municipal and industrial sectors. It’s primary goal is to remove solids, toxic pollutants, and pathogens, creating a safe, clean, and sustainable water source.

How is our SiC made?

Silicon carbide as a material is called upon to perform some pretty difficult tasks from armored vests to high-performance brakes, silicon carbide is used when all others have failed – makes sense to use it for membranes, doesn’t it?

Sand extracted from the north sea is combined with carbon to create the sic powder used to manufacture membranes. Makes sense to use a material crafted by water to treat water, doesn’t it?

Silicon carbide (SiC) powder is first mixed into a paste and extruded to form the membrane substrate. The substrate is fired at over 2,000 C to permanently bond the SiC grains to one another. After firing, the substrate is coated with another layer of SiC powder to form the micropores of the SiC membrane. Once coated the substrate is fired again to form a monolithic membrane plate. SiC plates are assembled into modules. SiC modules are assembled on top of one another to form stacks or towers.